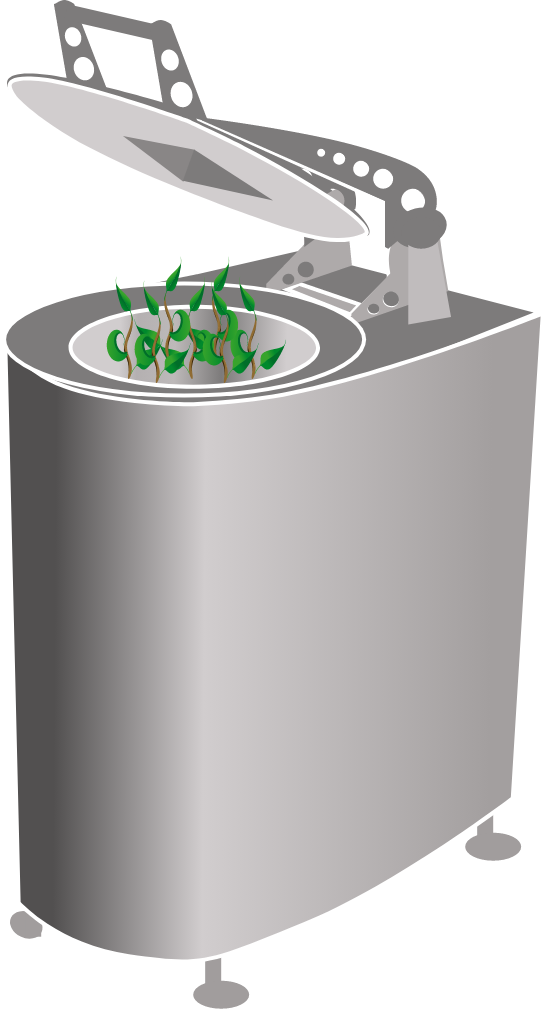

Enhanced rooting of Acacia cuttings with OptiBoost vacuum impregnation tech

OptiCept Celebrates Successful Test Results from Cuttings Pilot Project in Asia. The first partial results for Acacia cuttings treated with the patented vacuum impregnation technology shows great results.