A revolutionizing technology for ornamental cuttings

OptiBoost application for ornamental cuttings is a technology under development. We’ve seen great results for many ornamental plants.

OptiBoost application for ornamental cuttings is a technology under development. We’ve seen great results for many ornamental plants.

One of the major advantages of the OptiBoost method is the extended storage time it provides. With longer storage durations, the horticulture industry can benefit from more flexible, cost-effective, and eco-friendly transportation solutions. This improvement applies to both production farms and customer sites, including greenhouses across Europe.

Furthermore, the OptiBoost method enables better management of production peaks. By allowing cuttings to be harvested in advance and stored, growers can efficiently handle fluctuations in demand. Gone are the days when the harvest of ornamental plant cuttings was solely determined by customer orders. With the OptiBoost method, planning becomes more efficient, and the harvest can be organized based on available personnel or per variety.

Reducing waste is another significant advantage of the OptiBoost method. Instead of discarding unsold varieties, growers can store them and sell them later when market demand increases. This approach minimizes waste and maximizes profitability. Additionally, the OptiBoost method contributes to improving the quality of ornamental cuttings. After storage, cuttings exhibit enhanced general appearance, turgidity, and structure. Moreover, their development and rooting after planting are significantly improved.

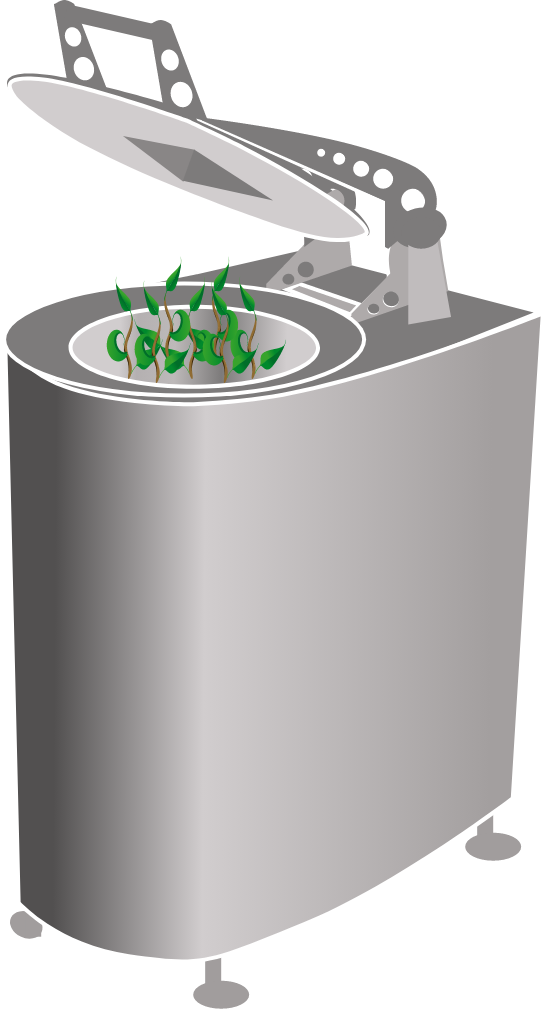

Optiboost technology is a symbiosis of two technologies. Vacuum impregnation and nanotechnology. We impregnate the cuttings with a functionalized nutrient solution based on the third generation of patented nanotechnology.

The vacuum impregnation technology introduces external liquids into porous structures such as plant tissue. The treatment chambers is optimized to enable the nutrient solution to efficiently reach the cells of the treated cuttings. The cuttings are impregnated with the optimal amount of solution.

The tissue is immersed in the liquid and subjected to a two-phase pressure change. The liquid infused into the material may have different properties, and VI can thus be used to change the composition of plant tissues. Different cuttings demands for different VI protocols, nutrient solutions (pressure parameters, treatment time, etc)

Want to learn more about the Optiboost technology?

Welcome to get in touch with any further questions, see contact details below. Or why not book an online meeting right away? Simply choose a suitable time in the calendar!

With the OptiBoost technology, we contribute to an extended, optimized, and more sustainable Cut Flower Experience. We help growers, wholesalers and retailers boost quality, increase sustainability and improve business.

Get the latest news from OptiBoost straight to your inbox